Top Deep Groove Bearing Supplier

Precision and Reliability

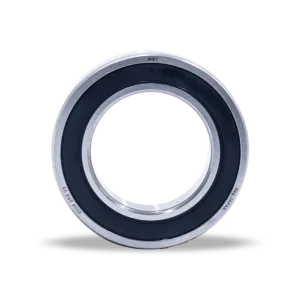

At BMT IMPEX, we are proud to be recognized as a Top Deep Groove Bearing Supplier. We know that in the world of machinery, the smallest components often make the biggest difference. Deep Groove Ball Bearings are the most versatile and widely used bearings in the industry, essential for reducing friction and ensuring smooth rotation in countless applications.

Materials and Build

When you partner with a Top Deep Groove Bearing Supplier, quality is non-negotiable. The lifespan and performance of a bearing depend entirely on its construction.

Material

High-quality deep groove bearings are typically manufactured from High Carbon Chromium Steel (Chrome Steel) for superior hardness and wear resistance. For corrosive environments, we also supply Stainless Steel variants that resist rust and moisture.

The Cage

The cage holds the steel balls in place. Depending on your speed and load requirements, we offer bearings with steel cages (for high strength), brass cages (for high temperatures), or polymer/nylon cages (for quiet operation).

Protection

To keep out dust and retain lubrication, these bearings come with Metal Shields (ZZ) for solid particle protection or Rubber Seals (2RS) for a tighter seal against liquids and fine dust.

Deep Groove Ball Bearing Specifications

| Bearing No | Inner Dia (mm) | Inner Dia (in) | Outer Dia (mm) | Outer Dia (in) | Width (mm) | Width (in) | Dynamic Load (Cr) | Static Load (Cor) | Number of Balls | Steel Ball Dia (mm) |

|---|

PRODUCT MODELS

Complete range of ball bearings for every application

Where Are Deep Groove Ball Bearings Used?

As a leading supplier, we serve a diverse range of industries. You will find our bearings powering equipment in

Electric Motors

Crushers, vibrating screens, and heavy conveyors use these bearings to handle rocks, dirt, and intense vibration.

Automotive

Your car’s wheels, gearbox, alternator, and water pump all rely on deep groove bearings to function smoothly.

Household Appliances

Washing machines, blenders, and vacuum cleaners all use them to spin quietly and efficiently.

Industrial Machinery

Conveyor belts, robotics, and machine tools use them to handle heavy radial loads and ensure precision.

Agriculture

Tractors and harvesters operate in dusty, muddy fields. Our sealed bearings (2RS) are specifically built to keep contaminants out in these tough conditions.

Mining and Construction

Heavy-duty sealed versions are used in crushers and screens to handle abrasive conditions.

Why BMT IMPEX is the Top Bearing Supplier for Your Business

Choosing the right supplier impacts your bottom line. Here is why industries trust us

Guaranteed Quality

Every bearing we sell passes strict quality checks. We ensure the dimensions, hardness, and noise levels meet international standards.

Huge Inventory

We stock a massive range of sizes, from miniature bearings to large bore ones. This means we can ship what you need, fast.

Expert Advice

Not sure which seal or cage material you need? Our team is here to guide you to the exact right choice for your application.